Industry 4.0 (I4.0) has already become a reality across industries and organizations with its unprecedented potential for higher flexibility, customization and efficiency levels. At the core, this is achieved through digitalized and interconnected industrial assets enabling data exchange between machines, humans, and enterprise systems. While benefits of I4.0 are obvious, less obvious and often ignored are the underlying physical and cyber risks introduced by changing configurations and interactions between digital assets, humans, property and the environment. This is particularly relevant to “Smart Manufacturing” systems which are flexible by design.

Safety and Security constitute two major challenges for all stakeholders of smart manufacturing – system designers, integrators, system owners and operators. Applying conventional risk assessment to dynamic I4.0 contexts that feature a multitude of interactions and data flows is becoming impracticable. At TÜV SÜD, we address this challenge with a novel solution: Adaptive Safety & Security System (AS3). AS3 assists you in navigating complex risk landscapes in both virtual environments and real-world applications.

Subscribe to our Telegram channel to get a daily dose of business and lifestyle news from NHA – News Hub Asia!

AS3 is based on a new method for dynamic risk assessment by means of “digital safety and security profiles“, processed by its inference engine against actual application constraints, providing automatic and instantaneous risk evaluations.

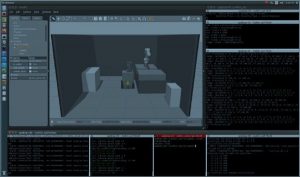

The new method was conceived and developed in Hong Kong by an international team of TÜV SÜD experts. Proof of Concept was realized in collaboration with the Cyber-Physical Systems department of Hong Kong Applied Science and Technology Research Institute (ASTRI) which is dedicated to using Model-Based Systems Engineering (MBSE) to design, synthesize and validate mission-critical systems for smart factories (I4.0).

Embedding safety and security into your I4.0 solutions builds trust and confidence with asset owners and operators. As part of the Digital Twins of industrial assets, AS3 can be used in the design phase for (off-line) risk assessment simulations and at runtime for instantaneous reaction to change events. AS3 can be interfaced with existing simulation tools and be hosted on enterprise platforms.

Ultimately, with AS3 you can control and reduce potential downtimes due to safety hazards and cyber security threats.

AS3 is under IP patent protection of TÜV SÜD Hong Kong Ltd.

SOURCE TÜV SÜD