According to DIC Corporation, DIC Develops Distinctive CeramNex™ AP10 Flake Alumina Filler

– Imparts outstanding strength and heat dissipating properties to electronics components and is expected to contribute to the proliferation of CASE vehicles and 5G-enabled devices

DIC Corporation announced today the development of CeramNex™ AP10, a distinctive flake alumina filler that imparts heat dissipating properties to components for electronics equipment and other applications. The new product is scheduled for launch in January 2021 and will be sold exclusively through trading firm Nagase & Co., Ltd. Going forward, DIC aims to expand the range of products in the CeramNex™ AP10 lineup and to achieve sales of ¥800 million by 2025, focusing on automotive and electronics equipment component manufacturers in Japan, the People’s Republic of China, the Republic of Korea, Taiwan, Europe and the United States.

The growing importance of the CASE (Connected, Autonomous, Shared and Electric) concept and the deployment of the 5G cellular telecommunications standard continue to drive the trend toward ever-smaller components with more sophisticated performance features in both the automobile and electronics industries. As a consequence, the dissipation of heat generated inside equipment is an increasingly important consideration. Alumina fillers, which offer superb thermal stability, are used to impart heat dissipating properties to automotive and electronics equipment components. Compounding formulations involving a large amount of alumina filler are common because they add thermal conductivity to resin, but a high filler content hinders moldability and reduces the mechanical strength of the resulting molded components.

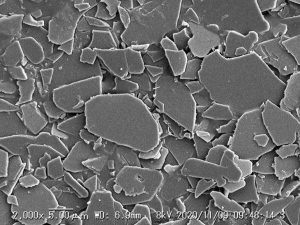

Unlike conventional alumina fillers comprising spherical or irregular particles, CeramNex™ AP10—which is synthesized using an original process—boasts excellent crystallinity and high aspect ratio flake-shaped particles. As a consequence, greater strength can be achieved with the addition of a smaller amount, thereby helping reduce weight. Moreover, superior surface uniformity means that DIC’s new product is suitable as an additive for applications in areas other than the automobile and electronics industries.

The DIC Group is working to create businesses in response to environment, safety and health (ESH)-related issues and social changes in line with its New Pillar Creation strategy. While efforts focus on businesses underpinned by organic materials technologies, the Group will build on the development of this products to add inorganic materials technologies to its portfolio, positioning it to expand into businesses that would have been problematic with its existing basic technologies.

SOURCE DIC Corporation