According to YCP Solidiance, Brother Machinery Asia and YCP Solidiance Highlight the Importance of Digital Transformation for the Apparel Industry

In their new report titled “Digital Transformation in the Apparel Industry: How to Improve Efficiency in Apparel Factory Supply Chain,” Brother Machinery (Asia) Limited (BMA) and YCP Solidiance unveil that digital transformation is inevitable for players who want to compete effectively in the Apparel Industry.

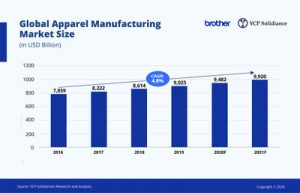

The global apparel market size has risen to USD 948.2 billion in 2020, recording a 5.1% increase from 2019. This market size is forecasted to grow to USD 992 billion in 2021, with the Asia-Pacific region accounting for more than 50%.

However, this overall perspective does not reveal the intensifying competition faced by players in the Apparel industry. With technology, competition among apparel players is no longer domestic, but on an international scale. Furthermore, the COVID-19 pandemic has accelerated the need to transform digitally. With apparel factories being forced to close, the apparel industry lost its functions and total sewing machine operating hours by 70% and 27%, respectively, in April 2020.

BMA and YCP Solidiance held a virtual webinar late December 2020 to address the current headwinds in the Apparel Industry and share strategies on how Apparel players can innovate to achieve success.

How the Apparel Industry can Succeed with Digitalization

The study revealed that some apparel brands (Uniqlo, Nike, and Adidas), have adopted digitalization in their business process, e.g. supply chain management software, allowing them to monitor the production better and create a more transparent supply chain flow.

As the Asian labor market is no longer the cheapest, digitalization allows apparel players to save costs in the long run. Hardware technology advancements, such as integrated internet of things (IoT) systems, have increased apparel production by 5% and reduced costs and production time by 88%.

“Digitalization in the apparel sector aims to maximize the power of data and further enhance the manufacturing production,” says Gen Kimura, General Manager at BMA.

The report also provides a framework for Apparel players looking to digitalize:

- Understanding needs: Identify current productivity problems due to manual processes.

- Prioritize strategically: Prioritize each problem by urgency and feasibility.

- IoT and data visualization: Use IoT to efficiently gather production data.

- Data analysis and action: Analyze data and identify points for improvement.

As more opportunities arise, digital transformation will help apparel businesses compete effectively and achieve success.

Download our whitepaper here.

SOURCE YCP Solidiance